Advantages of Marathon Enterprise Plastic Sheet Extrusion Process – Over 90% Long-term Partner Repurchase Rate

1. Diverse Raw Material Supply, Independent Procurement Control

Stable procurement of HDPE, PP, PE, ABS, and other plastics. Transparent sourcing and stable pricing ensure consistent quality.

2. In-house Extrusion Equipment, Stable & Consistent Quality

High-performance extrusion machines ensure uniform sheet thickness, smooth surfaces, and high production efficiency.

3. Professional Prototyping Service, Fast Adjustment & Verification

Supports small-batch prototyping for customized requirements, reducing communication time and mold validation processes.

4. Strict Quality Inspection, Certified by SGS and Others

Material, thickness, and mechanical strength can be tested to ensure compliance with customer specifications and industry standards.

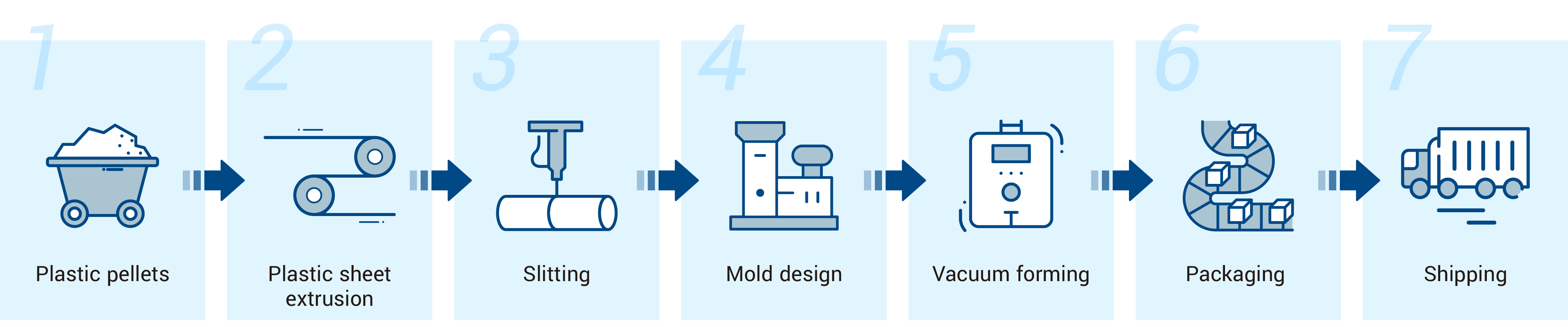

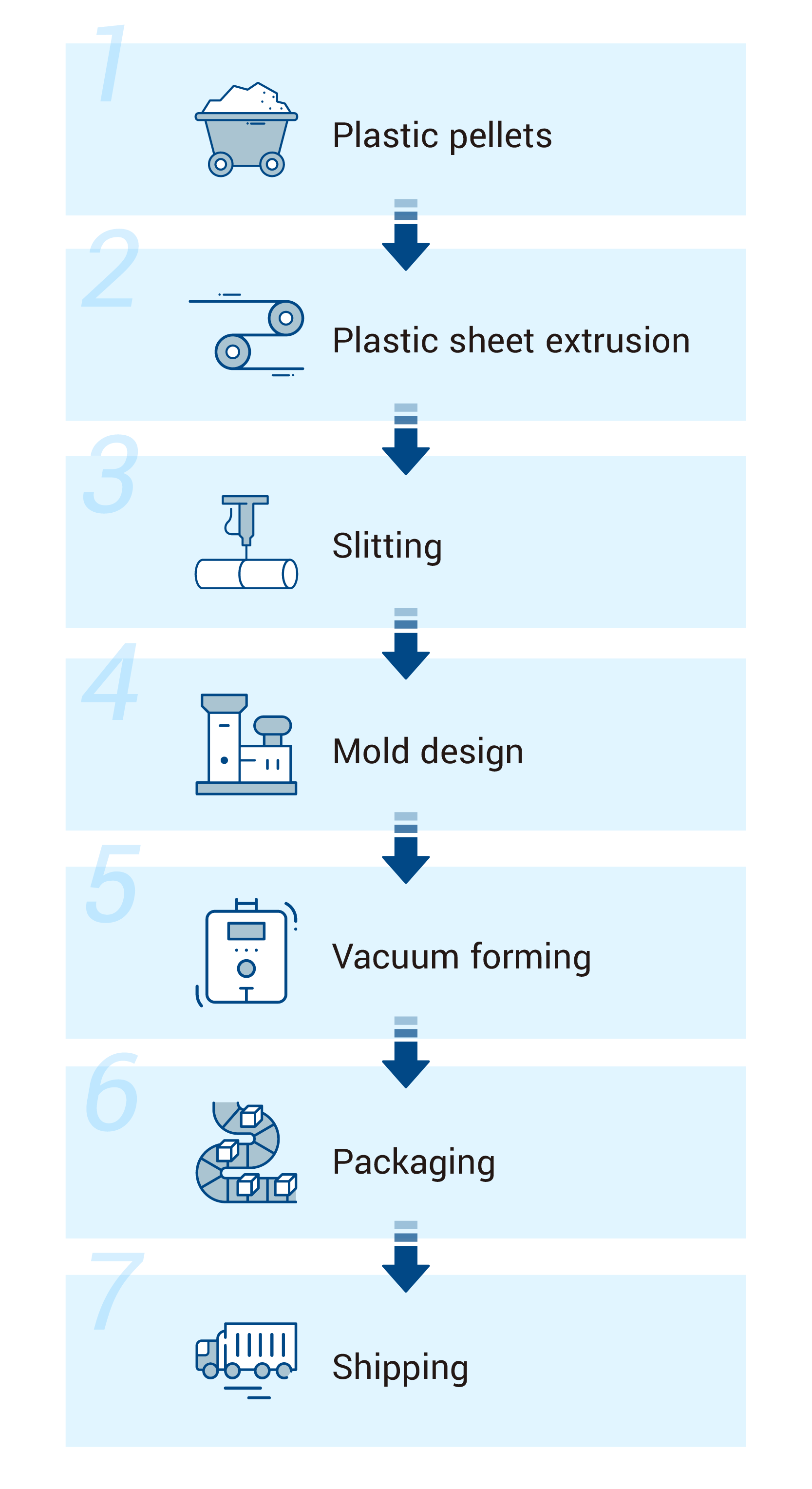

5. One-stop Process – High Efficiency & Fast Delivery

From raw materials → extrusion → slitting → mold design → vacuum forming → packaging → shipping, all completed in-house.

6. Highly Flexible Customization, Wide Applications

Plastic sheets can be cut to size, adjusted in thickness, and surface-treated (e.g., anti-static). Widely used in electronics, medical, food, and hardware industries.

7. Stable Quality & High Repurchase Rate

Reliable processes and consistent quality earn customer trust. Long-term partner repurchase rate exceeds 90%.