Why Choose Marathon Enterprise? Your One-stop Partner for Plastic Sheet & Blister Manufacturing

Ten Key Advantages – Complete Vacuum Forming Solutions, All in One!

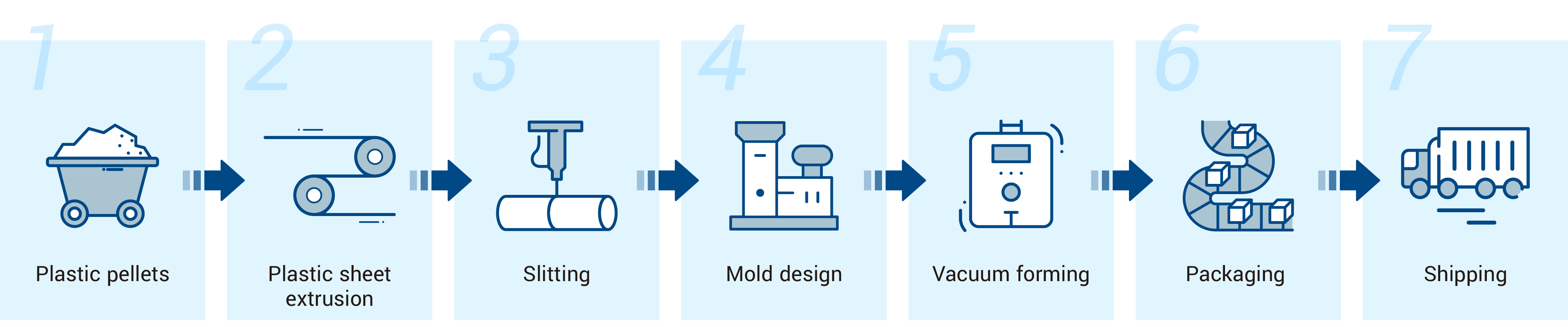

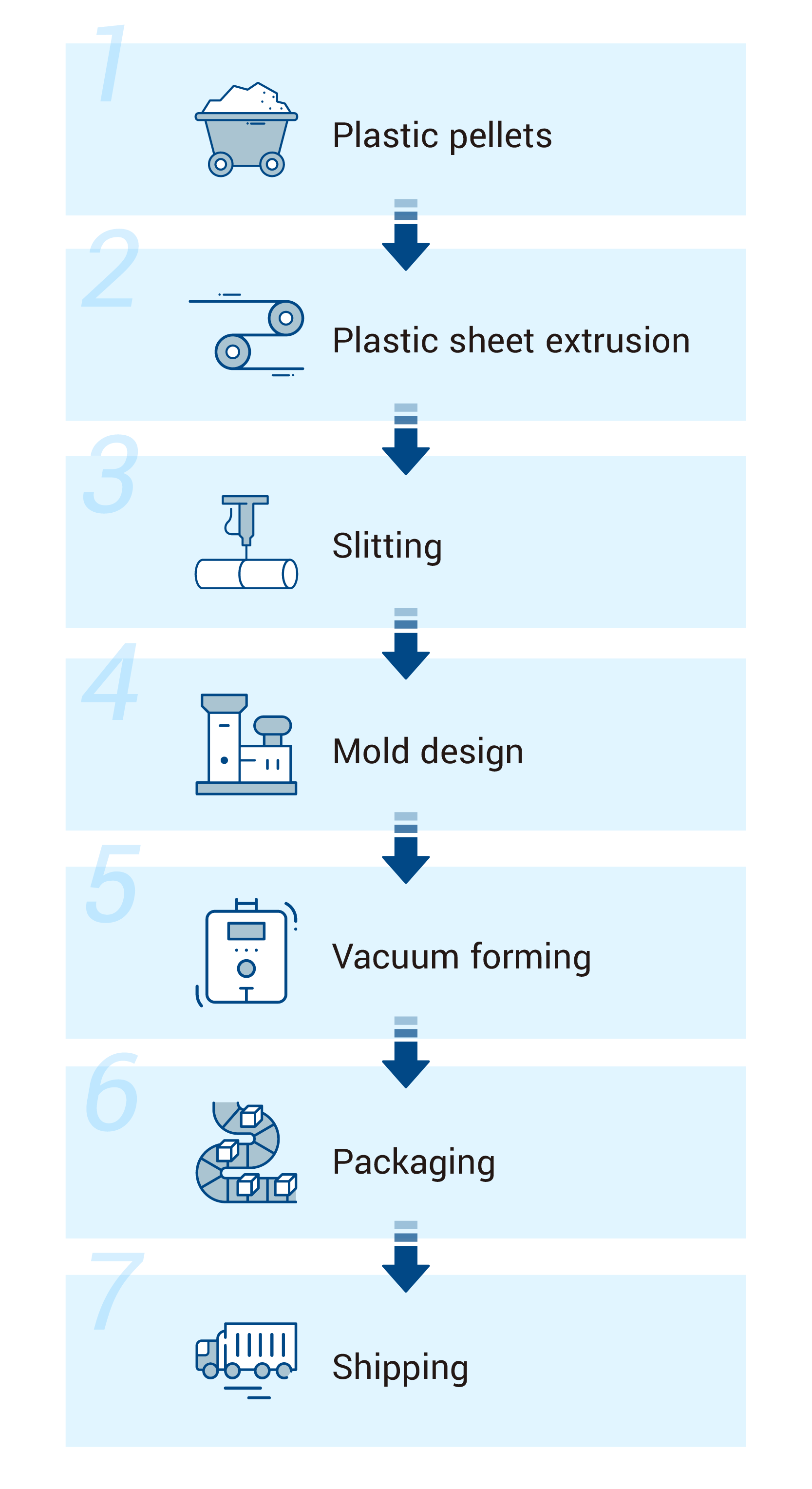

1. One-stop Integrated Manufacturing

Plastic sheet extrusion + vacuum forming + mold design, all in-house. Saves time and reduces risks from coordinating with multiple suppliers.

2. Save Development Time & Cost

Rapid prototyping and centralized production shorten project schedules and significantly reduce overall costs.

3. High Flexibility in Customization

Materials, sizes, thickness, and functions (anti-static / conductive) can all be tailored to specific applications.

4. Fast Delivery & High Efficiency

Equipped with high-performance imported extrusion machines, ensuring quality control and flexible scheduling. Prototypes can be delivered in as little as 3–5 days, with mass production handled efficiently.

5. In-house Mold Design & Development

No reliance on external mold makers—reduces risks, speeds up revisions, and ensures confidentiality.

6. Stable Quality & Controlled Processes

• Food-grade certification: Complies with SGS standards for food-contact safety.

• Full in-house process control eliminates quality fluctuations or delivery delays caused by outsourcing.

7. Single Point of Contact, Smooth Communication

Dedicated service from quotation, design, mold-making, prototyping, to delivery—seamless support throughout.

8. Diverse Material Options with Professional Advice

Expertise in HDPE, PP, PE, ABS, and more, recommending the most suitable materials based on product requirements.

9. Applications Across Multiple Industries

Trays are widely used in electronics, food, medical, hardware, cosmetics, and more, backed by extensive experience.

10. Support for Special Processing & Packaging

Additional services include slitting, cutting, anti-static treatment, packaging, and logistics—truly an “all-in-one manufacturing solution.”

| Item | Description |

| Process Integration | Raw materials, extrusion, vacuum, molds, prototyping, packaging—all in-house |

| Delivery Efficiency | Dedicated machines & in-house mold development, faster scheduling |

| High Customization | Flexible design for materials, sizes, and functions |

| Cost Advantage | Avoids outsourcing & rework, enabling precise budget control |

| Professional Team | 20+ years of manufacturing experience, reliable expertise |