Tray & IC Tray – What Marathon Enterprise Can Do for You

You focus on product sales—we take care of manufacturing!

1. Stable Raw Material Supply – Control Costs and Quality at the Source

Direct procurement of various plastic pellets (HIPS, PP, PE, ABS, etc.) ensures stable prices and quality, minimizing risks from external supply fluctuations.

2. In-house Extrusion Machines – High Consistency

Using high-quality extrusion equipment, sheet thickness is uniform and properties stable, reducing warping or deformation after forming.

3. Professional Slitting and Cutting

Pre-cutting materials according to product size reduces waste, improves production efficiency, and meets various machine or mold feeding requirements.

4. In-house Mold Design and Manufacturing

Our team designs and manufactures molds internally, ensuring designs fit the extrusion and forming process, allowing fast revisions and maintaining confidentiality.

5. Mature Vacuum Forming Technology – Wide Applications

With in-house sheets and molds, we precisely control temperature, pressure, and vacuum accuracy to improve product integrity and detail reproduction.

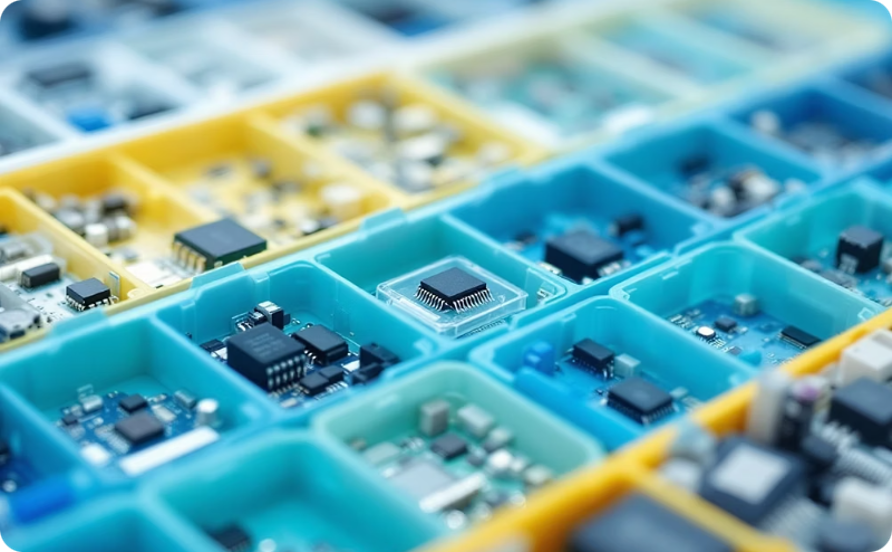

6. Highly Customized Tray & IC Tray Products

Dimensions, shapes, materials, and functions (anti-static / conductive / food-grade) can be customized. Widely used in packaging, protection, and transportation of components in electronics, semiconductors, medical, food, logistics, and warehousing industries.

7. Fast Prototyping – Accelerated Development

With in-house prototyping and mold-making, samples can be completed in as fast as 3 days, shortening development timelines.

8. Single Point of Contact – Save Communication & Integration Costs

No need to coordinate separately with raw material suppliers, extruders, mold makers, and formers—Marathon manages the entire process efficiently.

9. Strict Quality Control – Supports SGS / RoHS Testing

From raw materials to final products, we can coordinate with third-party testing to ensure compliance with industry standards.

10. One-stop Service – Short Lead Time, High Flexibility

With integrated internal processes (raw material → extrusion → forming → packaging → shipping), we shorten lead times and respond quickly to urgent or changing orders.

Applications Across Industries

Electronic IC Trays

Medical Equipment Liners